Thermal Energy Storage systems are essential to achieve net-zero economies as they enable a number of industries - including pulp and paper, food, textile and chemical - to make the transition from fossil fuels to a competitive and reliable green heat energy generation.

MGTES is the Electro Thermal Energy Storage system that helps to achieve the decarbonization

of industrial processes and power systems on the path to sustainable development.

MGTES technology

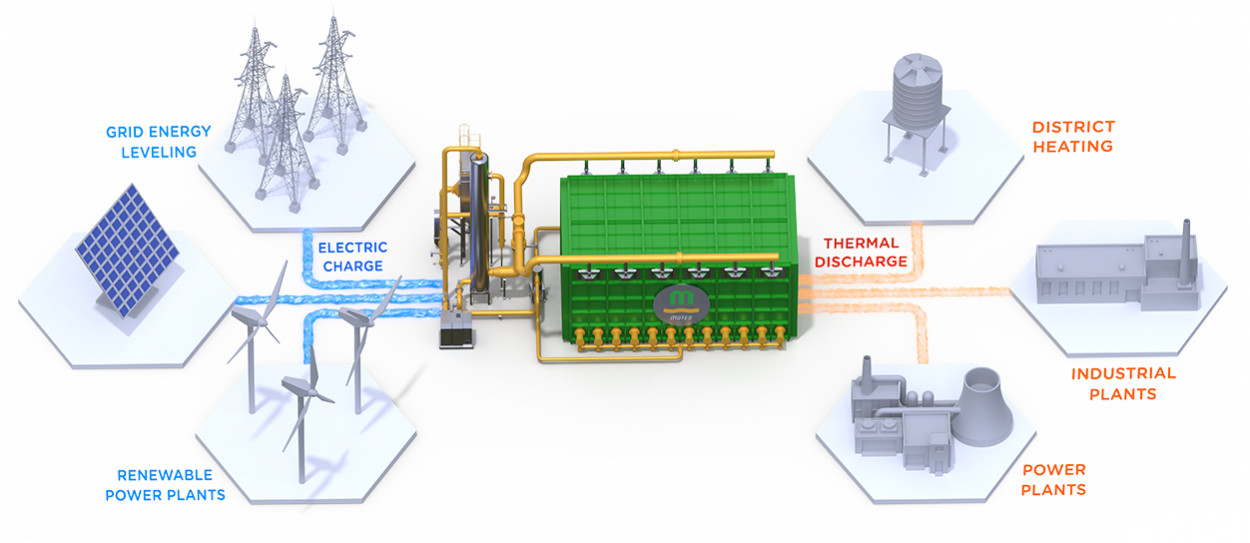

MGTES is a patented and innovative system for thermal energy storage, based on a fluidized sand bed. Once charged with renewable energy or directly from the grid, the system can store clean energy for hours, days, or even weeks to release 24/7 high-temperature thermal energy (e.g. hot steam), continuously or not.

How does the sand-based thermal energy storage work?

Charge and Discharge simoultaneously

Long Duration Energy Storage MGTES charges when renewable energy is available, stores energy through sand, and releases heat for industrial uses continuously. This enables it to solve the problem of intermittency of renewable sources.

It can also be charged directly from the grid when electricity prices are lower than those of natural gas, using intelligent energy management softwares.

MGTES operates in 3 phases:

Charge: Solid particles bed can be heated by using electrical heaters or high temperature fluid. In this phase the fluid bed is active.

Storage: The fluidization is switched off, and the sand packs at the bottom of the module allowing the absorbed energy to be stored for days or even weeks with minimal energy losses.

Discharge: Thermal accumulated energy is released to the heat transfer fluid typically superheated steam (up to 600°C) or other high temperature fluids required by industrial processes.

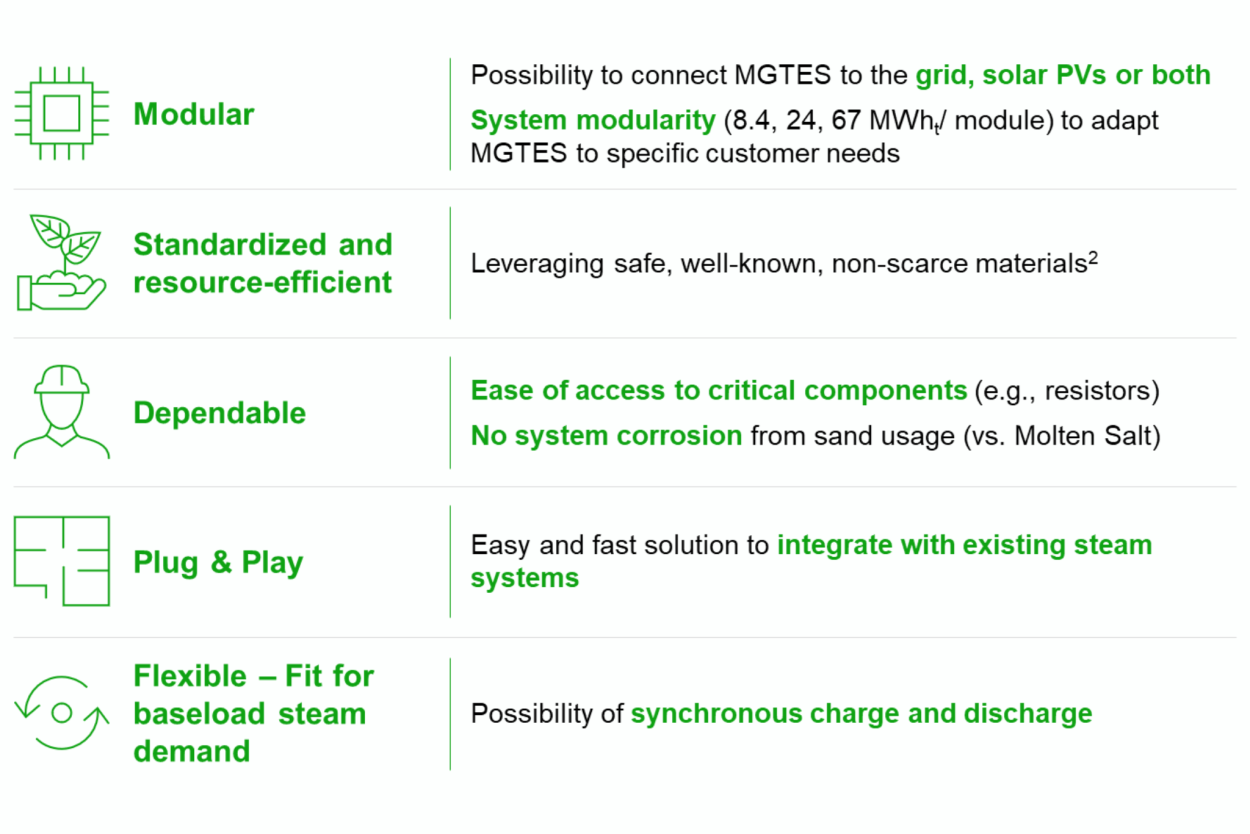

Distinctive features of Magaldi Green Thermal Energy Storage

Modular technology

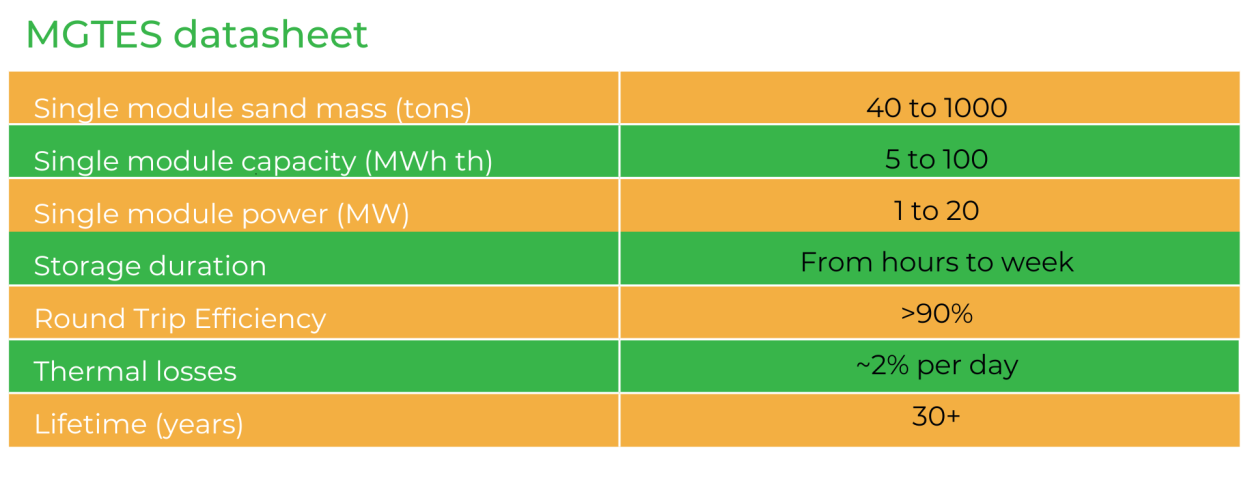

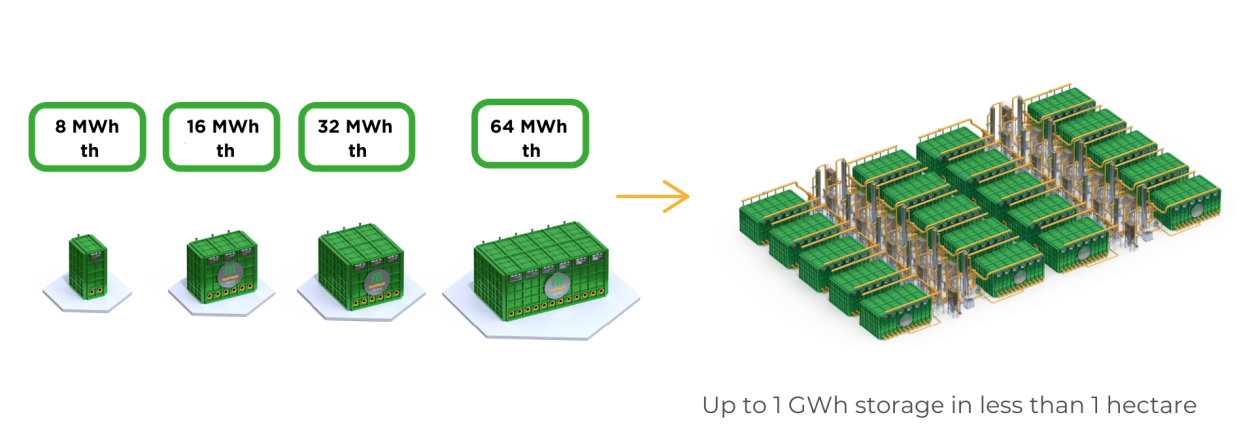

The modular design of the MGTES technology offers significant flexibility to suit the demands of the customers in terms of process temperatures, storage times, and demand patterns. By selecting the mass of solid particles contained in each module, thermal storage capacity of a single module can be configured over a wide range starting from 5 MWh to 100 MWh

Decarbonisation of high temperature industrial processes

MGTES represents the bridge between the power and industrial sector, responsible for most greenhouse gas emissions. 74% of energy demand of industry is used for process heat. MGTES produces green superheated steam (or other high temperature fluid) for a wide range of industrial applications: Food and beverage, Pulp and paper, Chemical, Desalination

Discover the MGTES applications

Go to Power-to-Heat Applications

Brochure's download

Go to the Download section to get the brochure.