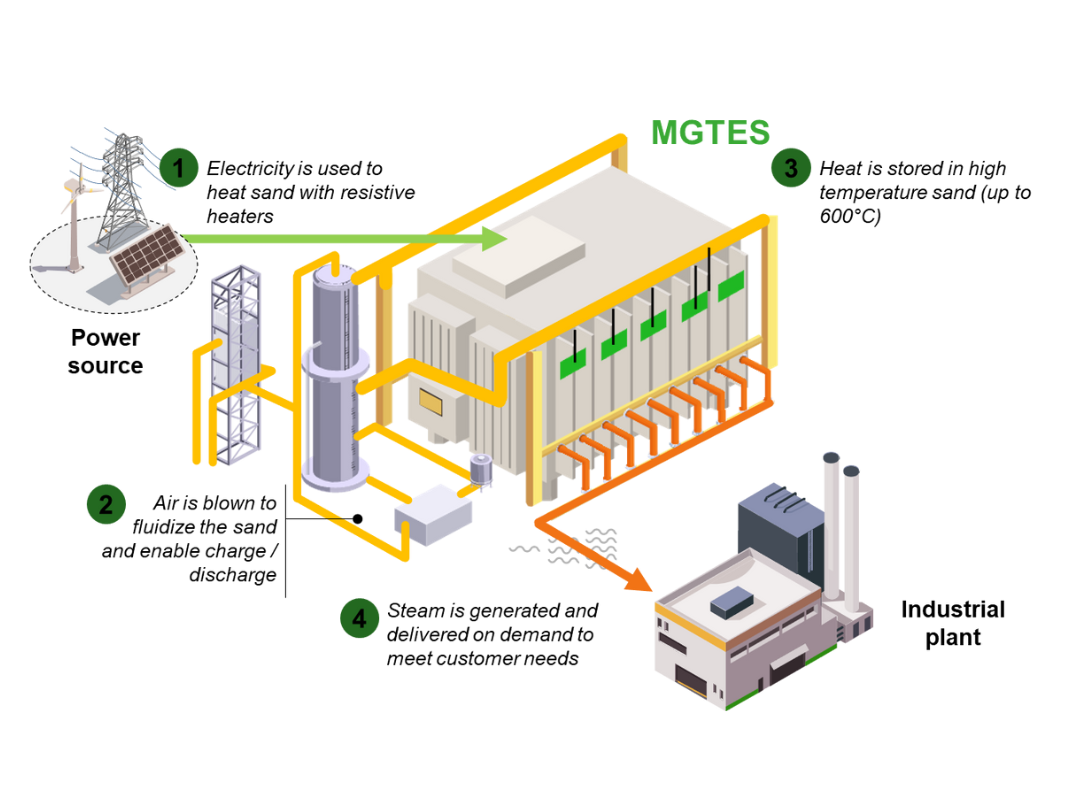

MGTES for thermal power production

Heat accounts for approximately 45% of energy related emissions and more than 50% of global energy consumption. Industrial applications constitute the largest share of heat consumption, amounting to 40% of the total heat demand, and around 70% of this demand is met by fossil sources.

Heat electrification – made possible by the integration of renewable energy sources with thermal energy storage technologies- is an effective decarbonization option.

MGTES delivers Power to Heat services, useful for different applications and market segments, including the industrial sector, the civil sector, district heating and so on.

For such applications, MGTES is able to:

- Absorb the surplus electricity generated by non-programmable renewable power plants or directly from the grid.

- Convert this energy into sensible heat, which is stored in the fluidizable bed of sand particles.

- Release on-demand the stored thermal energy to the heat transfer fluid, typically superheated steam up to 450°C.

Major advantages

- Electrification of high temperature industrial thermal processes

- Reduction of fossil fuel consumption and CO2 emissions thus minimizing carbon footprint

- Industrial waste heat recovery from intermittent industrial processes

- Provision of Demand Response services

- Balance the electricity grids characterized by high penetration of non-programmable renewable energy plants, reducing curtailments

- Increase the flexibility of an existing CHP (Combined Heat and Power) plant, decoupling the generation of electrical energy from the thermal one

- Carbon neutral district heating

- Increase the energy self-sufficiency and protection from highly volatile energy prices

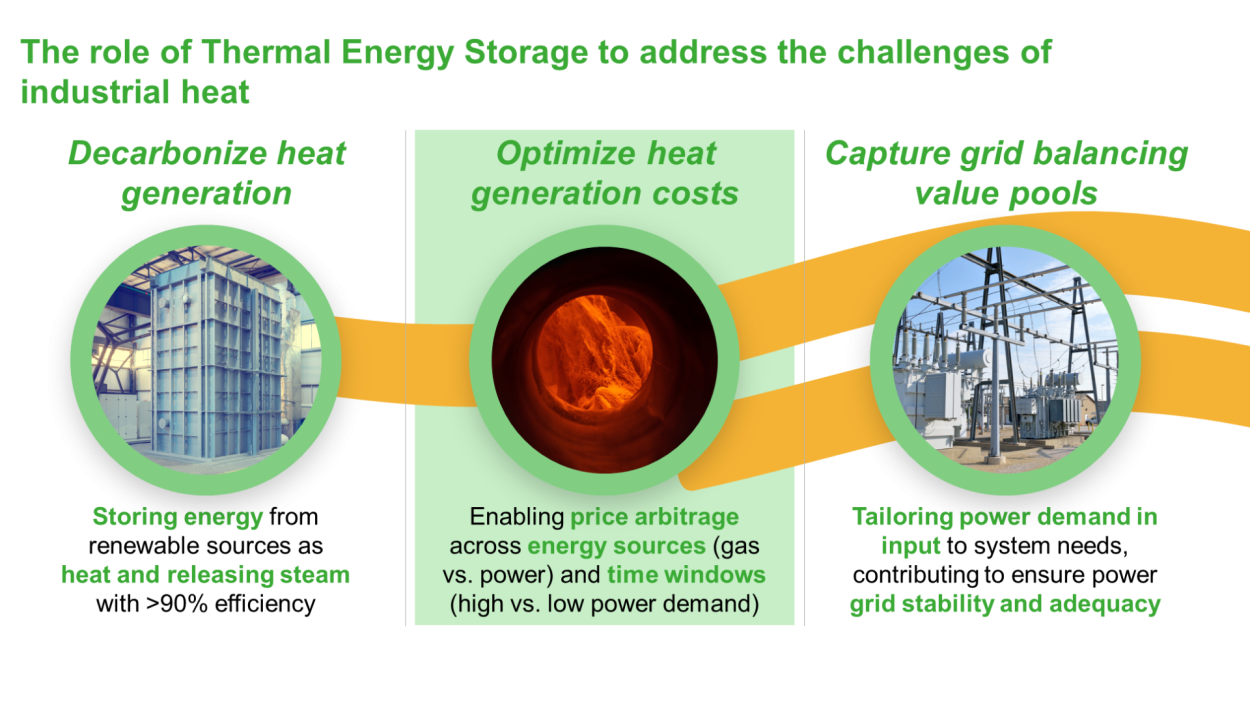

Combined with renewable energy, the Green Heat stored by MGTES can replace traditional fossil fuel generation; thus, MGTES can dramatically reduce CO2 emissions.

Decarbonization of industrial processes

Decarbonization of industrial heat is crucial to reach net zero and Thermal and Electro-Thermal Energy Storage systems are a commercialy and technically available solution for building low-carbon, competitive and resilient energy systems.

By electrifing industrial heat, TES and ETES systems could reduce the equivalent of up to~40% of 2022 global gas use and the equivalent of up to 14% of global energy-related greenhouse gas (GHG) emissions by mid-century.

The MGTES system is charged by renewable electricity. During charging phase, a system of resistors heats up to 620°C the bed of fluidized solid particles and, during discharging phase, steam generators immersed in the sand release steam at pressure of 10 to 40 bar, and temperature spanning 150 to 450°C (248-752 degrees Fahrenheit). Moreover, it is an easily available and worldwide applicable solution, due to its composition made only of steel and sand (abudand storage material).

"Power to Heat" applications enable electrifying industrial processes and bringing green heat energy to various contexts.

Industries that can benefit from the advantages of MGTES

A Sand Based Technology ideal for many applications

MGTES is the Worldwide patented Thermal Energy Storage based on fludizable sand bed technology. Compared to molten salts, solid sand particles, used as heat storage media, are stable over 1000°C and can operate at both lower and higher temperatures than molten salts, subject to freezing and melting phenomena.