How a simple TES technology can drive global manufacturing decarbonization

If heat goes "green," so does the planet. The ecological transition relies on the decarbonization of industrial processes, and a substantial portion of industrial energy consumption is dedicated to heat production.

Heat accounts for about half of the global energy demand. Industrial heat, in particular, is responsible for one-fifth of the global energy demand, representing a significant share of energy-related carbon emissions. (McKinsey, Global Energy Perspective, 2022)

Making the heat used by the food and beverage industries, as well as pulp & paper production industries, sustainable would represent a significant step towards a development model that is both cost-effective and environmentally friendly.

Industrial heat: myths about alternatives to gas

Habit often prevails over convenience. One mistake a competitive business can never afford to make is to continue doing things a certain way just out of habit. Alternative technological solutions to the use of fossil fuels for heat production in industrial processes, particularly gas, are already on the market and easily adoptable, yet many companies are still unaware of them.

"Although electrification offers a clear path towards decarbonization" says a recent McKinsey report, Net-zero electrical heat: A turning point in feasibility, "the lack of awareness of commercially available low-carbon industrial heating technologies, such as TES thermal energy storage, has caused hesitation. A better understanding of commercially available technologies could help industrial companies advance in electrification".

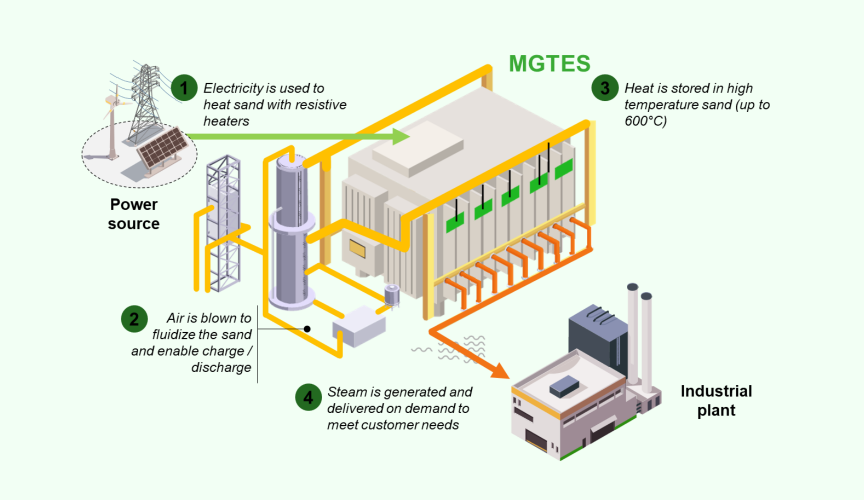

TES Thermal Energy Storage, an economical and straightforward solution

It’s still not widely recognized that thermal production, which accounts for about half of Europe's energy demand, can shift from fossil fuels to renewable-based technologies and storage solutions, like our MGTES system. This was recently highlighted in New Scientist by BBC journalist Roger Harrabin in an article with the telling title "How incredibly simple tech can supercharge the race to NET Zero: These systems allow prices to remain low by recovering much of the heat wasted from industrial processes or the heat generated from renewables during periods of excess production, using extremely simple technologies such as resistors to convert electricity into heat”.

Investments paid back in one year

Last but not least, the costs. The McKinsey report also highlights the financial benefits of investing in the electrification and storage of industrial heat. "Electricity is often already cheaper than gas. On one hand, the on-site costs of renewable energy sources are decreasing. On the other, grid electricity prices are becoming lower during periods of excess supply. Together, these elements make a strong case for considering the electrification of heat in an industrial context. The economic potential of electricity combined with thermal energy storage is supported by the decreasing costs of renewable energy generation". Under the right conditions, the analysts emphasize: "Electrification could pay for itself within a year”.

Learn more about our MGTES Thermal Energy Storage System.